1. What is a grating plate made of aluminum?

A lightweight, corrosion-resistant metal grid product, aluminum grating plates are created by joining aluminum bars in a predetermined spacing pattern; these bars are typically welded, press-locked, or swage-locked together. In commercial and industrial settings, it is frequently utilized as flooring, walkways, and safety platforms.

Aluminum grating is superior to steel grating in terms of strength-to-weight ratio and corrosion resistance, which makes it perfect for harsh environments like outdoor, chemical, and marine applications.

A variety of alloys with varying degrees of strength and corrosion resistance are frequently used for aluminum grating plates, including 5052 aluminum grating plates, 6061 aluminum grating plates, and 6063 aluminum grating plates.

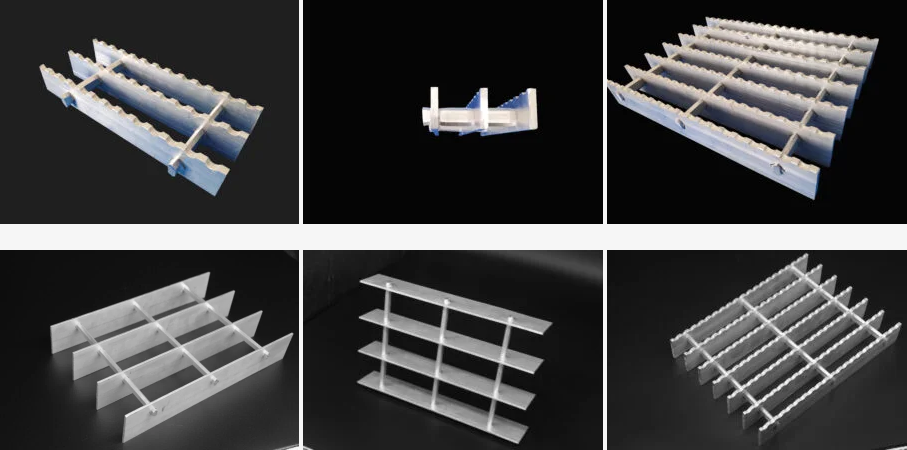

2. Primary Aluminum Grating Types

Welded Aluminum Grating: For a sturdy and inflexible structure, crossbarsare welded to the bearing bars. For maximum strength, 6061-T6 or 6063-T6 aluminum is frequently used in production.

Press-Locked Aluminum Grating: This type of grating has a smooth, consistent appearance because the crossbarsare mechanically pressed into the bearing bars. Architectural 5052-H32 aluminum grating plates can be used with it.

Swage-Locked Aluminum Grating: For exceptional durability, crossbarsare locked under high pressure after being inserted into pre-punched holes.

Serrated Surface Grating: Often found in 5052 aluminum serrated grating plates, bearing bars feature serrated edges to increase their resistance to slippage.

3. Principal Benefits of Aluminum Grating

Strong but Lightweight: Compared to steel grating, this material is up to 50% lighter while still having a high load-bearing capacity.

Superior Corrosion Resistance: Marine-grade alloys, like 5052 aluminum grating plates, are resistant to harsh chemicals and saltwater.

Slip Resistance: In wet or greasy conditions, safety is guaranteed by serrated designs.

Low Maintenance – No painting or galvanizing required, especially for 6063-T6 aluminum grating plates.

Aesthetic Appeal: A sleek, architecturally appropriate metallic finish.

4. Typical Uses of Aluminum Grating

Industrial Platforms and Walkways: For heavy-duty load capacity, 6061-T6 aluminum grating plates are used in factories, refineries, and power plants.

Marine and Offshore Structures: For corrosion resistance, 5052-H32 aluminum grating plates are frequently used on oil rigs, ship decks, and docks.

Drainage Covers and Trench Gratings: Smooth-finished 6063-T6 aluminum grating plates are advantageous for municipal infrastructure projects.

Architectural Facades and Sunshades: Decorative 5052 or 6063 aluminum grating plates are used in modern building designs.

HVAC systems and equipment screens composed of lightweight 6061 aluminum grating plates are known as airflow and ventilation panels.

5. GNEE Guide to Selection

When choosing aluminum grating plates, take into account:

Load Requirements: 6061-T6 is recommended for heavy loads; bearing bar thickness and spacing must satisfy structural requirements.

Surface Type: Serrated to prevent slippage, smooth for aesthetics.

Corrosion Environment: 5052 aluminum grating plates exposed to chemicals and the sea.

Production Method: Press-locked for appearance, welded for strength.

Verify that the grating satisfies ASTM ,GB or EN standards.

In conclusion, aluminum grating plates combine strength, safety, and resistance to corrosion, especially when made of alloys like 5052, 6061, and 6063. In industrial, marine, and architectural applications, aluminum grating can offer decades of dependable performance with little maintenance if the proper alloy, surface treatment, and structural design are used.