what is Aluminium Gratings

Aluminum grating is a lightweight material that is an alternative to steel grating. Forged bar grating is mechanically locked to the load-bearing bars through crossbars, and all nodes between the load-bearing bars and crossbars are welded through formed structures to provide high load-bearing capacity.

GNEE offers aluminum and stainless steel forged bars, and can custom fabricate carbon steel forged bars upon request.

Aluminum bar grating is available in a variety of options, such as: rectangular grating, I-beam grating, flat top grating, and riveted grating. Load-bearing grating sizes range from 1″ x 1/8″ to 2-1/2″ x 3/16″, with depths in 1/4″ increments. Load-bearing grating spacing is 7/16″ to 1-3/16″, with crossbar center spacing of 2″ or 4″.

GNEE rectangular grating is available with a serrated surface if non-slip properties are required.

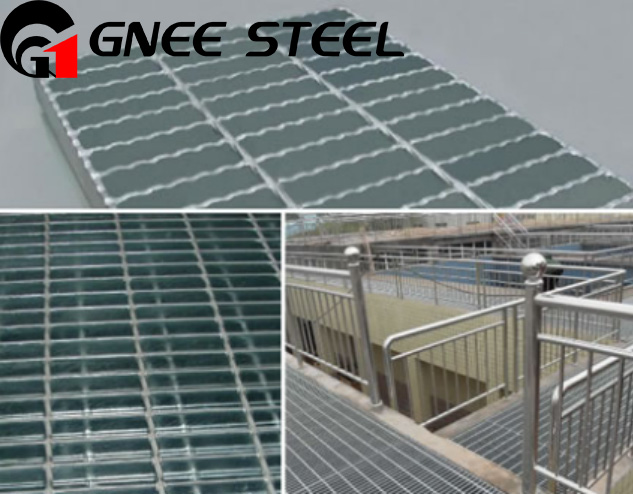

Aluminum grating is corrosion-resistant, non-sparking, and rust-resistant, making it ideal for use in corrosive environments. It is widely used in sewage treatment plants, refineries, chemical plants, pumping and compressor stations, and walkways and platforms on ships and barges.

Because it does not rust, aluminum grating is often used in breweries, bottling plants, and food processing and storage facilities. Its non-sparking properties make it a necessity for safety protection in munitions factories and other flammable and explosive industries and fields. It is available in standard or anodized surface finishes.

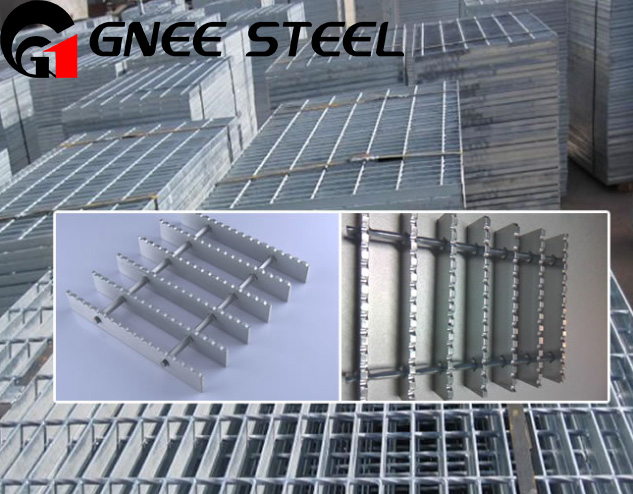

Forged Grating

Crimped aluminum grating is manufactured with either an “I” shaped or rectangular bearing bar. These

bearing bars are permanently locked to the crossbars through a forging process that reshapes the

crossbars. I-beams reduce the open space of the grating due to the flange width, but I-beam

lock patterns are lighter weight and maintain their load ratings. Lock pattern I-beam grating is the most

widely available and offers comparable strength to rectangular bars of the same depth, but at a much lower

weight. Rectangular crimp locks are available with the crossbars flush with the top of the bearing bars,

or with the crossbars closer to the middle of the support bars. These options are available if a specific look is desired.

Dovetail Grating

Dovetail grating is made of two close tolerance slotted bars bonded together (positioning

Every 2 inches or 4 inches using huge hydraulic force on the rectangular bar. Permanent locking is

Achieved by pressing deep crossbars into the bearing bars. Crossbars and bearings

Grate with press-lock design provides walking surface. Rectangular grating with

When lateral stiffness is required, press-fit or press-lock are your best choices.

Rectangular bars also come with serrated surfaces for added traction and safety.

Rectangular v I-beam grating

Both rectangular and I-beam aluminum gratings offer comparable strength.

Rectangular bars offer a variety of crossbar configurations, either flat or serrated.

I-beams are used only in swaged connections and are usually striped. This type of steel is more rigid than

Rectangular bars are a good choice for any project with weight restrictions.

Press-Fit Locking Aluminum Grating is assembled by inserting hollow tube crossbars into pre-punched load-bearing bars through a crimping and reshaping process. Because the crossbars are recessed below the top surface of the bar, this type of grating has clean lines and an eye-catching appearance.

Versatile Press-Fit Aluminum Grating offers a variety of grating sizes, is lightweight and portable, corrosion-resistant, and high-strength. The open mesh structure allows light, air, and moisture to flow easily, requiring virtually no maintenance.

Manufactured to tighter tolerances than other types of grating, Press-Fit Aluminum Bar Grating is ideal for a variety of applications. These applications include entryways, security barriers, outdoor vents, decorative grating, awnings, fencing, infill panels, channel grating, and bridge walkways.