6061 aluminum is more corrosion resistant than 7075 aluminum because the copper content in the 7075 alloy is higher than in 6061. Since copper is more reactive to the environment, the higher the content, the more corrosive it is, and 6061 aluminum has more applications in industries where corrosiveness is a concern than 7075 aluminum.

In terms of weight, 7075 aluminum has a higher strength-to-weight ratio than 6061 aluminum. They are preferred for lightweight applications, such as making lightweight frames for better handling and greater combat range. In terms of strength-to-weight ratio, 6061 aluminum is rated at 115 KN-m/Kg, while 7075 aluminum is rated at 196 KN-m/Kg.

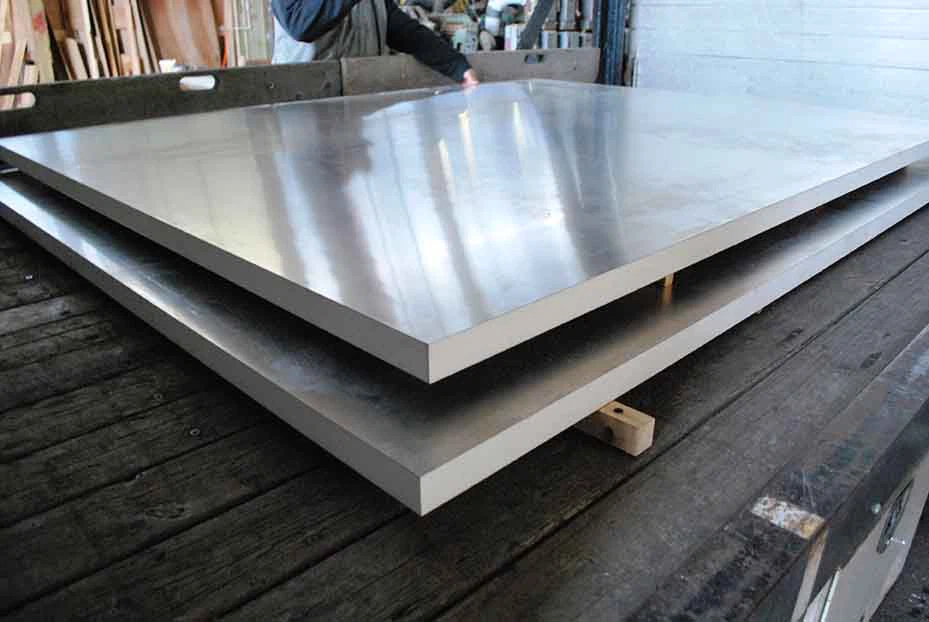

6061 aluminum is more cost-effective, moderately strong, and easy to work with, while 7075 aluminum is very strong and usually has a smoother surface but costs more. 6061 aluminum is used more frequently than 7075 aluminum, primarily because of the cost difference.

In terms of welding performance, 6061 aluminum is weldable, while 7075 is generally considered difficult to weld and machine. Because of its lower hardness and tensile stress, 6061 aluminum alloy may have an advantage in scenarios that require good machining performance and welding performance.

The 6XXX series alloys are ideal for anodizing. The oxide layer after the anodizing process is clear and provides excellent protection, and 6061 aluminum is the first choice of many machine shops when parts need to be hard anodized in a variety of colors. 7075 aluminum is also very suitable for anodizing, but if the zinc content is too high, they may anodize to gray, blue-gray, or brown (mottled color).

When looking at both alloys in the “T6 temper,” it is noted that the tensile strength of 7075-T6 aluminum is almost twice that of 6061-T6 aluminum. It is estimated that the shear strength of 7075-T6 is 1.5 times that of 6061-T6. Therefore, 7075 T6 aluminum is also significantly harder than 6061-T6.