1. What are the common applications of 1060 aluminum checker plate?

1060 aluminum checker plate is commonly used in applications requiring anti-slip surfaces and light-duty strength. These include:

Truck bed floors and trailer ramps

Cold storage room walls and floors

Stair treads and platforms

Decorative wall cladding and ceilings

In the H24 or H14 temper, 1060 aluminum tread plate provides enough hardness to resist wear while maintaining easy formability. Compared to other aluminum sheet and plate products, its high aluminum content (>99.6%) ensures excellent corrosion resistance in humid and low-temperature environments.

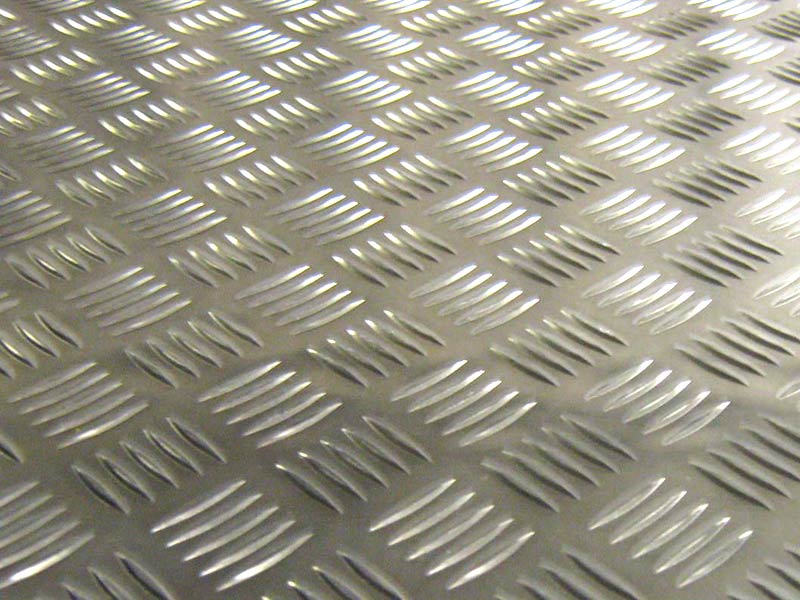

2. What surface patterns are available for 1060 aluminum checker plates?

Customers often ask about the texture options on 1060 aluminum checker sheet. Common surface patterns include:

Five-bar aluminum checker plate

Diamond aluminum tread plate

One-bar or single-rib patterns

These surface textures not only offer anti-slip functionality but also enhance aesthetics, making 1060 embossed aluminum plate popular in both industrial and architectural settings.

3. What is the difference between 1060 checker plate and 3003 checker plate?

Both 1060 aluminum checker plate and 3003 aluminum tread plate are widely used, but they differ in strength and corrosion resistance:

1060 checker plate: Higher purity (99.6% Al), better electrical conductivity, lower strength, better suited for cold storage, cladding, and lightweight floors.

3003 checker plate: Alloyed with manganese (approx. 1.2%), offering higher strength and better performance under load—ideal for truck ramps and heavy-duty flooring.

Customers seeking more structural durability often compare these options, depending on the application environment and budget.

4. What tempers are available for 1060 aluminum checker plate?

GNEE’s 1060 aluminum checker plate is available in various tempers to meet processing and performance needs:

1060-H14 aluminum checker plate: Semi-hard, good for light fabrication and forming

1060-H24 aluminum tread plate: Medium-hard with enhanced wear resistance

1060-O aluminum checker sheet: Soft condition, used for forming and shaping

Each 1060 aluminum alloy plate temper affects the mechanical properties and suitability for specific applications. GNEE offers tailored cutting and forming services for each use case.

5. How does GNEE ensure quality for 1060 aluminum checker plate products?

At GNEE, our 1060 aluminum tread plate products undergo strict quality control:

Uniform thickness and flatness

Consistent pattern depth and clean surface finish

Protective PVC film or paper interleaving upon request

Optional anodizing or color coating for decorative or corrosion resistance needs

We offer 1060 patterned aluminum plate in standard and custom dimensions, with fast lead times and global shipping.

Conclusion

1060 aluminum checker plate remains a preferred material for customers who need corrosion resistance, decorative surface finishes, and anti-slip performance in lightweight applications. With flexible temper options like 1060-H14, 1060-H24, and 1060-O, and variants such as five-bar aluminum checker sheet and diamond tread plate, this product is adaptable across industries.

Choose GNEE for high-quality 1060 aluminum checker plate, precision cutting, and custom surface treatments that meet your exact project requirements.