Technical Data Sheet

| Chemical Composition Limits | |||||||||

| Weight% | Al | Cu | Si | Fe | Mn | Mg | Zn | Cr | Others |

| 5052 | Bal | 0.10 max | 0.25 max | 0.40 max | 0.10 max | 2.2 / 2.8 | 0.10 max | 0.15 / 0.35 max | 0.05 max (each) 0.15 (total) |

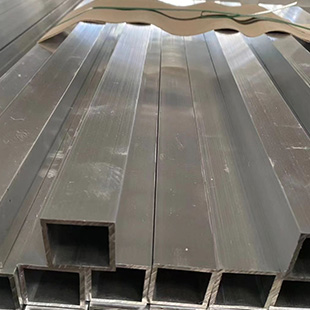

Technical characteristics of 5052 aluminum alloy tubing

As a corrosion-resistant aluminum tubing, 5052 aluminum tubing is particularly well suited for use in marine environments. The alloy is particularly good at resisting corrosion in seawater environments and is commonly used in equipment such as evaporative condensers in desalination systems.The technical characteristics of 5052 aluminum tubing include:

Cold-drawn seamless tubing: ensures high strength and quality.

Elemental control: Strict control of the content of elements such as silicon, zinc, copper and iron ensures the stability of material properties.

Rare earth element reconstruction: Reconstruct Mg2Al3 and Mg5Al8 by adding rare earth elements to improve the corrosion resistance of the material.

Beautiful corrosion curve: excellent corrosion performance in seawater test.

Application areas and working conditions

5052 aluminum tubing is widely used in a variety of equipment and structures that require corrosion resistance and high fatigue strength. Specific application areas include:

Seawater desalination systems: particularly suitable for low-temperature multi-effect distillation desalination systems (LT-MED), which can be operated at a maximum temperature of 75°C, a maximum pressure of -0.1 MPa, and a working medium of 7% seawater and steam.

Ship and marine components: Due to its excellent corrosion resistance, 5052 aluminum tubing is widely used in ships and other marine components.

Fuel and oil lines: Suitable for fuel and oil lines in aircraft and other transportation vehicles due to its high strength and good vibration resistance.

Industrial and domestic equipment: including sheet metal working, electrical appliances and lighting equipment.

Is GNEE a trading company or a manufacturer?

GNEE is an integrated trading and manufacturing company to better serve our customers.

Will the products I order from GNEE be delivered on time?

Yes, we are committed to providing the highest quality products and delivering them on time, punctuality and honesty are the core principles of our company.

Do you provide product samples? Are they free?

GNEE provides supply to customers free of charge, but customers need to bear the express freight.

Do your products undergo third-party inspection?

Yes, GNEE is fully third-party inspected to ensure transparency and quality assurance.

How does GNEE ensure product quality?

Each product is produced in a qualified workshop, and GNEE has obtained US FDA certification, EU ROHS compliance, SVHC compliance, and ISO quality management system certification.