Surface treatment is one of the key links in the manufacturing of aluminum foil coils. Its main purpose is to improve the corrosion resistance and adhesion properties of aluminum foil to ensure that it performs well in various applications. The steps of surface treatment usually include the following:

First, the surface of the aluminum foil needs to be thoroughly cleaned to remove any dirt, grease or other impurities that may be present. This is usually accomplished using chemical cleaners and water rinsing.

Second, the cleaned aluminum foil surface is chemically treated. This may include processes such as acid or alkaline washing to improve the quality of the surface and to remove oxidized layers to improve adhesion.

Finally, some aluminum foil coils may also require special coatings to be applied to the surface. These coatings can provide additional protection against corrosion and also improve the surface properties of the aluminum foil, such as reducing adhesion and making it easier to package or print.

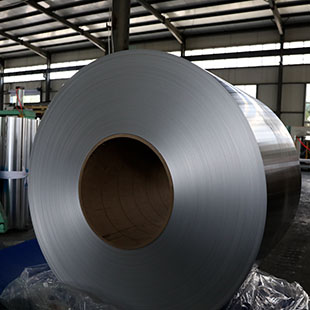

In addition to surface treatment, rolling is one of the key steps in the manufacture of aluminum foil coils. Rolling is the gradual reduction of the thickness of an aluminum block through the use of multiple rolling passes. The steps in this process include the following:

First, during the hot rolling stage, the aluminum block is heated to a temperature at which it is susceptible to plastic deformation. This allows the aluminum block to be gradually reduced in thickness through a series of roll mills in a subsequent cold rolling step.

Next comes the cold rolling stage. In the cold rolling stage, the aluminum foil is cooled and passed through a series of roll mills to further reduce its thickness. This step is usually repeated several times, each time pressing the foil thinner. This cold rolling process helps to improve the surface quality and flatness of the aluminum foil.

Finally, the rolled aluminum foil coils are cut to the desired dimensions to produce a foil coil product that meets the customer's requirements.