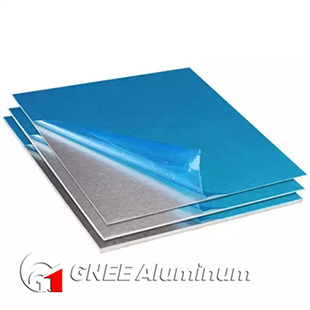

| Property | 5052 Aluminum Sheet |

|---|---|

| Alloy Type | 5052 |

| Temper | H32, H34, H36, H38, O |

| Density | 2.68 g/cm³ |

| Tensile Strength | 210 MPa – 305 MPa (30,000 psi – 44,000 psi) |

| Yield Strength | 83 MPa – 228 MPa (12,000 psi – 33,000 psi) |

| Elongation | 12% – 25% |

| Hardness (HB) | 60 – 95 |

| Application | Marine, Automotive, Aerospace, Architectural, General Engineering, Transport, Consumer Electronics |

5052 Aluminum plate performance:

1, good corrosion resistance

2, excellent weldability

3, good cold processing

4, and with moderate strength

Qualification Certificate

Cooperative Customer Display

Packing and Transportation

GNEE Group is a large-scale modern comprehensive enterprise focusing on raw materials and deep processing of raw materials for aluminum sheet and foil. The company is located in Anyang City, Henan Province. Established in 2008, the company is a leading aluminum producer in China and one of the largest aluminum foil producers in China. The main products are aluminum sheet, aluminum bar, aluminum coil and aluminum foil.

1、Strong strength

GNEE Aluminum factory covers an area of 133.200 square meters, with 8 workshops, including 6 equipment workshops, 1 packaging workshop and 1 finished product workshop. There are 163 employees in the factory, including 18 managers, 6 technical engineers, 3 quality inspectors, 17 packaging staff, 9 logistics staff and 12 sales staff.

And the total number of overseas customers is more than 563.

2、Advanced equipment

GNEE Aluminum has introduced six-roll cold rolling mill from Simak, Germany. The width of aluminum plate is up to 2650mm, the thickness is up to 500mm, the internal stress is eliminated, and the cutting is not deformed, so it is one of the few manufacturers in China that can produce ultra-wide and ultra-thick aluminum plates.

3、Complete products

GNEE Aluminum is a large aluminum alloy listed enterprise, specializing in the production of aluminum plate, aluminum coil, aluminum foil. The product categories cover 1-8 series alloy grades. GNEE Aluminum accepts large orders, can quote RMB/foreign currency prices, and exports globally.

Advantages of GNEE Aluminum Sheet:

Product diversity: our aluminum panels offer a wide range of product lines and specifications covering different alloy types, sizes, surface treatments and processing states to meet a variety of customer needs.

Fast delivery: GNEE has perfect supply chain management and inventory control to deliver products in time to meet customers’ urgent needs.

Environmental awareness: GNEE Aluminum focuses on environmental protection and sustainability and is committed to reducing its impact on the environment through the use of green production processes and material recycling.

Price competitiveness: The company is able to offer competitive prices under the premise of guaranteeing the quality of its products, providing customers with more valuable products and services.

Good reputation and word-of-mouth: GNEE has a good reputation and word-of-mouth in the industry, and has earned the trust and support of its customers through continuous quality service and customer satisfaction.